The Best Guide To Welding Shops Near Me

Wiki Article

Some Ideas on Arc Welder You Should Know

Table of ContentsMig Welder Fundamentals ExplainedSome Known Details About Arc Welder Indicators on Mig Welder You Need To KnowHow Spot Welder can Save You Time, Stress, and Money.The Definitive Guide to Underwater WeldingRumored Buzz on Smaw

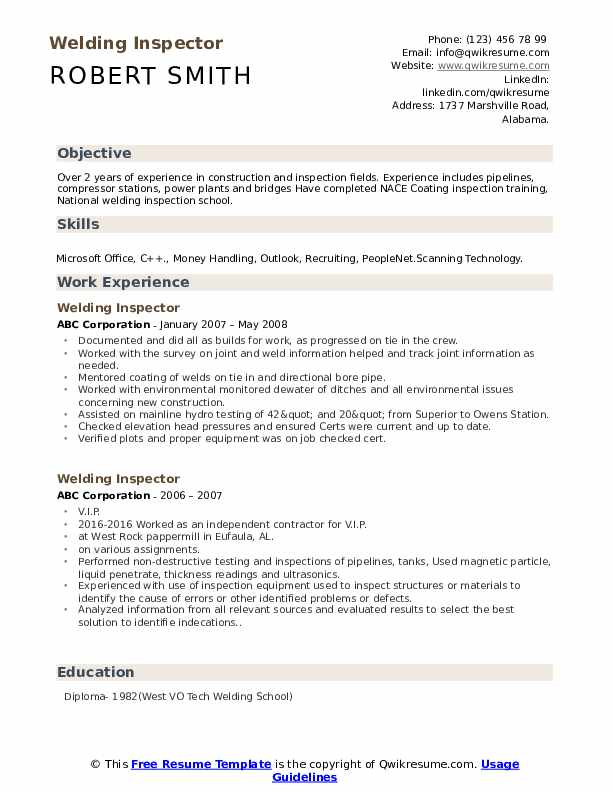

Understanding of how to determine the different weld quality needs using specialized weld determines and the like. Fundamental knowledge of Non Destructive Screening (NDT) demands and also capacities. While the data base is essential to get welding examiner tasks, simply as vital is having the best individuality for the work.The pressure positioned on welding inspectors by manufacturing employees when a Does Not Comply (DNC) phone call is made can be really considerable. If you experience stress and anxiety when having to taking on strong willed people, this may not be the job for you. If this does not phase you, after that this facet of the welding inspector job should not create you excessive stress and anxiety.

A regular example being CSWIP in the UK. An additional company that is taking a leading function globally in the accreditation of employees for welding assessor tasks is the International Institute of Welding. (IIW) The International Institute of Welding is in fact rather an old organization, however its influence on the certification side of things is actually just rather recent.

Arc Welder Fundamentals Explained

Please keep in mind that it is not possible to come to be a specialist in all welding codes. There are way also many. If you are currently a Welder and you wish to start getting direct exposure to welding codes to make sure that you can prepare on your own for a life as a welding assessor, then I suggest you focus on the complying with codes: ASME IX: This is geared to the welding of pressurized tools such as piping as well as pressure vessels.

1: This is geared towards architectural steelwork. American based, however extensively used worldwide. API 1104: This is geared towards pipeline welding. American based. Use relatively extensively, although pipeline codes do have a tendency to have a more local bias. Most of the more neighborhood pipeline welding codes are freely based on API 1104, so an excellent basis to have.

Little Known Facts About Welding Table.

It is made use of globally, yet the major usage is in Europe. While the codes above are good beginning factors, there are countless different codes, standards as well as specs that the welding inspector will require to obtain an understanding of. These requirements take care of subjects as diverse as welding consumables, base materials, harmful and also non-destructive screening techniques, high quality monitoring systems and also the like - smaw.You get to recognize the base codes, additional resources and afterwards you basically obtain to know the others via "at work" training throughout the Visit Your URL years. The certain requirements and also codes hing on your specific sector. The larger exposure you obtain to codes and also standards, the far better a welding inspector you will certainly be.

High Quality Systems Understanding Central to the job of the welding assessor is the quality control and control feature - arc welder. This is not just based on technological welding expertise, however likewise high quality systems knowledge. Within this part of your work you will certainly obtain to deal a whole lot with high quality management system criteria such as the ISO 9000 collection of criteria, as well as additionally the ISO 3834 series of criteria.

The Single Strategy To Use For Smaw

Quality Assurance (QA) as well as High Quality Control (QC) are greatly driven by documented systems and also count on records and documents to have traceability as well as an auditable system. All of this will be central to your work as welding assessor. If you are excessively daunted by documentation, then you might not take pleasure in the life of a welding examiner.The Welder, Destiny Compass: Weekly e-zine Subscription.

Assessors measure welded items to link make sure that they fulfill requirements for measurement. The licensed weld assessor makes use of tension tools to place stress and anxiety on weld joints.

Unknown Facts About Cold Welding

Welding inspectors videotape the results of examinations as well as welding assessments. An university education and learning is not required for many welding or welding evaluation positions, but an associate level in welding technology can improve the possibilities of landing a task.

Something went wrong. Wait a moment and also try again Attempt again.

The Ultimate Guide To Welding Shops Near Me

Elderly Team Engineer, National Board This short article was originally published in the Fall 2009 National Board Notice as the initial of a two-part series. Note: The objective of this post is to offer examiners with a basic expertise of weld evaluation.

While not necessary, the inspector should discover to review typical weld symbols such as the AWS signs. smaw. At the really least, the inspector should always carry a recommendation guide to interpret weld symbols. Having examined all this details beforehand, the inspector will be prepared to identify any kind of problems as they establish as opposed to after-the-fact.

The supplier or fixing company (certificate holder) has shown on the job drawing that a weld joint is to be prepared with a 60-degree bevel as well as origin void of 1/16 inch. Unless the bevels are milled on precision equipment, it is doubtful they will achieve a precise 60-degree bevel as shown.

Report this wiki page